Junior Process Engineer

OTI Lumionics

Operations

Mississauga, ON, Canada

Posted on Oct 2, 2024

About Us

OTI Lumionics is developing advanced materials—by design—using quantum simulations, machine learning and real-world testing in pilot production. We are currently focused on key enabling materials for OLED displays that will be used in next-generation consumer electronics and automotive. Our advanced electrode materials, and associated manufacturing technology, are being used to build transparent displays and lighting. We work closely with our partners and customers to design new materials that are mass-production ready. Using our computational Materials Discovery Platform, we are able to rapidly iterate new materials, allowing fast turn around time to meet our customers’ needs.

Primary Responsibilities

· Design and conduct experiments for development of OTI’s materials using R&D equipment.

· Design and conduct experiments for development of new applications with R&D equipment using OTI’s materials.

· Perform maintenance tasks of R&D and/or production equipment and the laboratory according to SOP (Standard Operating Procedure).

· Follow SOP to performsample testing and analysis of experimental data, which may include but not limited to transmittance and reflectance measurements of thin film samples, OLED device performance measurements such as IVL (current-voltage-luminance) characteristics, OLED degradation measurement, etc.

· Document and report test results accurately.

· Assist in the development and validation of material purification process.

· Assist in developing SOPs for device fabrication and testing.

· Assist facility engineers in repairing, modifying and setting up new equipment.

· Provide feedback to software engineers on potential improvement to programs and software for R&D and/or production equipment developed by OTI Lumionics.

· Perform all tasks in accordance with established Safe Work Practices and Standard, Operating Procedures.

· Must have the ability to work all shifts (e.g. morning and evening shifts, weekend shifts, and holiday shifts).

Profile

· Post-Secondary Degree in Science/Engineering or equivalent combination of education and experience

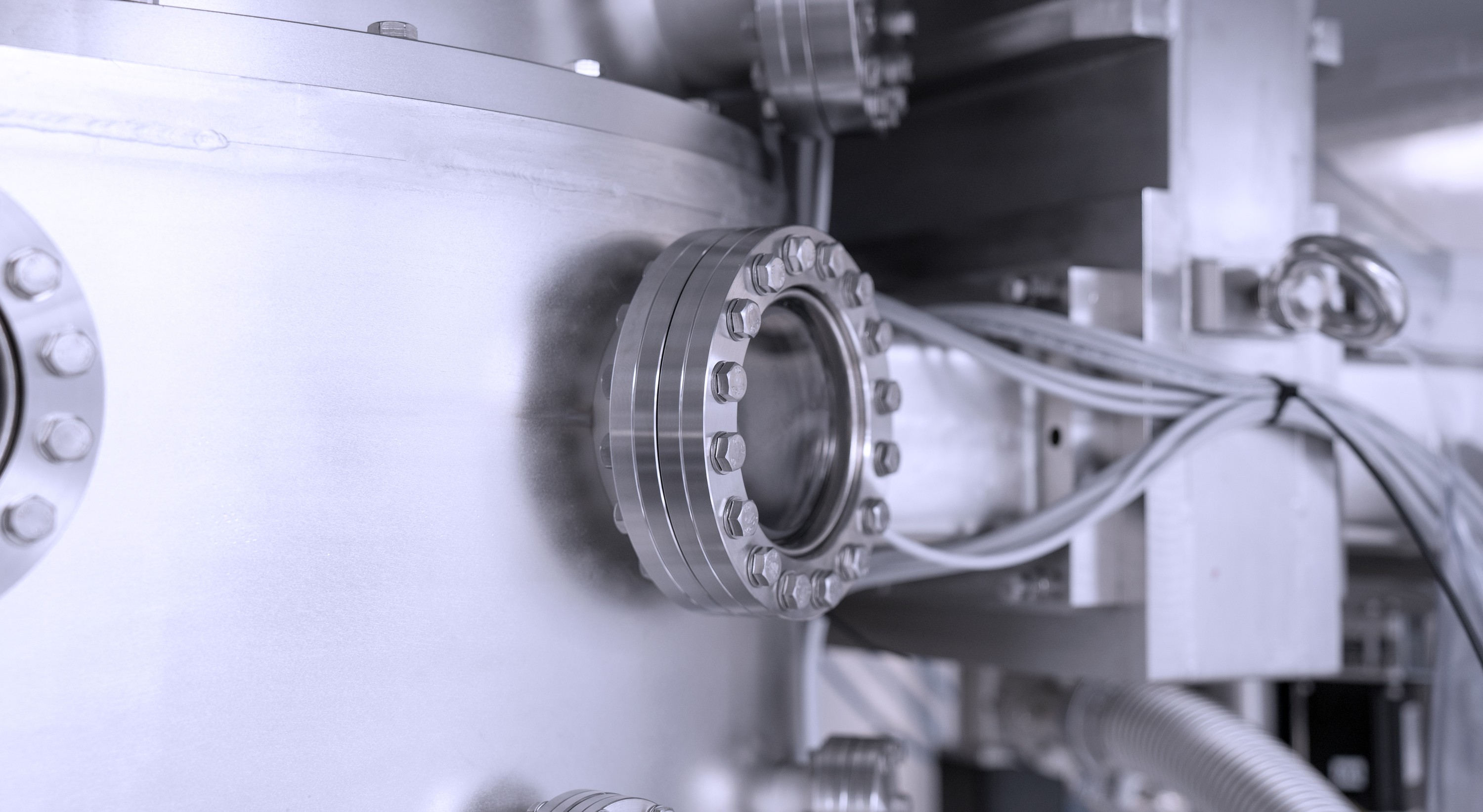

· 2+ years of industrial experience with vacuum equipment or equivalent post-graduate experience (e.g. MSc, MASc, PhD).

Required Skills

· Excellent hands-on skills

· Excellent understanding of processing engineering (i.e., design-of-experiment, root-cause analysis, process optimization)

· Excellent problem-solving and troubleshooting skills

· Excellent organizational, time management, analytical and follow-up skills

· Strong communication skills and be able to work effectively in a team environment

· Knowledge of vacuum science and thin film fabrication

· The following will be considered as an asset

· Experience of thin film fabrication (e.g. thermal evaporation, sputtering, ion plating, pulsed laser deposition, chemical vapor deposition, etc.)

· Experience of working in a cleanroom

· Experience of working in a chemical or pharmaceutical production environment